- [email protected]

- +86-21-63353309

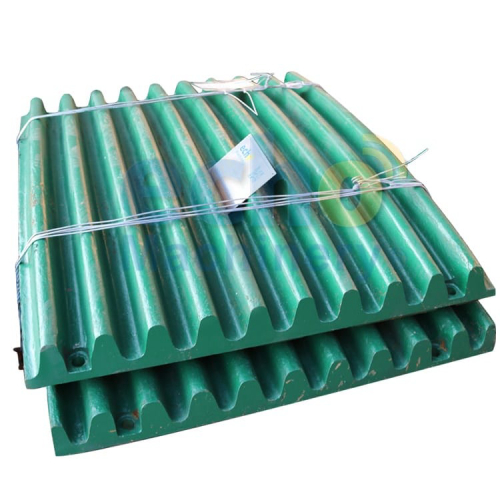

rubber mill liner

rubber mill liner

Home [ballmillrubberliner.com

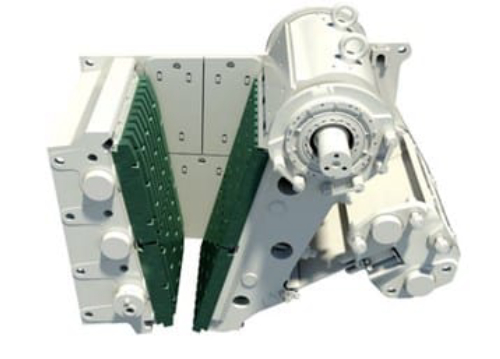

Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grind-ball. At the same time we can use different forms of the shell liners Read More, HEAD LINERS (TRIANGLE)

Learn MoreVulco® Mill Lining Systems | Weir Group

Weighing 35-40% less than steel, rubber and metal cap liners are faster and safer to install; Rubber liners significantly reduce the generated and transmitted sound level associated with grinding; Custom-designed to deliver similar service life for high- and low-wear zones of the mill, achieving a lower Total Ownership Cost (TOC) for your circuit

Learn More60 Duro Mill shell & liner backing rubber | Mill Backing - Reglin Rubber

AVAILABLE SIZES. Mill Backing Lining Rubber can also be supplied in cut lengths, strips, pads and a wide variety of custom cut shapes and gaskets to suit your application requirements. PART NUMBER. DESCRIPTION. WEIGHT (PER L/M) MB061200. Mill Backing Rubber With Buffed Back 6mm x 1200mm (10 L/M Rolls) 9.7 kgs. Product Information Sheet.

Learn MoreRubber Liner Rubber Liner Ball Mill Liner in Factory Price

Introduction of rubber liners. The rubber liner is gradually replacing the manganese steel liner. It can bear strong impact of resistance.

Learn MoreRubber Mill Liners Market Analysis (2022-2028), Product Overview and

Global "Rubber Mill Liners Market" In the forecast period of 2022-2028 is expected to grow at a steady rate, according to the Rubber Mill Liners Market report, which summarizes the key aspects

Learn MoreRubber Ball Mill Liner | Vostosun - Mineral Processing

The density of these wear resistant rubber liners is about 1/6 that of steel rubber liners, which reduces the cylinder weight, which in turn reduces the motor load during operation. The rubber ball mill liner material features a special structure, and has been formed using a high pressure vulcanization process. Gallery

Learn Morerubber mill liners - China Factory, Suppliers, Manufacturers

rubber mill liners Manufacturers, Factory, Suppliers From China, The principle of our company is to provide high-quality products, professional service, and honest communication. Welcome all friends to place trial order for creating a long-term business relationship.

Learn MoreBall Mill Liner ( Rubber , Polyurethane ) | Mill Rubber Linings Plate

The Lining Plate Of Ball Mill Is Gradually Replaced By Rubber And Polyurethane Lining Plate In China, But With The Continuous Application Of Rubber Polyurethane Lining Plate In The Lining Plate Of Ball Mill, It Has Gradually Replaced Manganese Steel And Other Lining Plates And Become The Mainstream Of Market Development.

Learn MoreBall mill Rubber lining - Kedar Rubber Products

Advantage of Ball Mill Rubber Lining ; 1. Reduced Weight · The rubber lining parts are about 1/4 less weight of brick liners of same size. ; 2. Reduced Power

Learn MoreTeknikum® Rubber Mill Linings

Teknikum® Rubber mill Linings are manufactured from wear resistant rubber material. The rubber materials are specially developed for mining and grinding mill

Learn MoreGrinding Mill Liners - Mineral Processing & Metallurgy

Rubber liners absorb the impact of the larger grinding media and thus protecting - the mill structure and prolonging it's life. Weight: Rubber weighs about 15% of an equivalent volume of steel. This means that a rubber liner system reduces the load on the mill structure and also reduces the basic power draw.

Learn MorePolycorp - Rubber Liners

Rubber Mill Liners are extensively used in FGD mills at Power Plants all over the world. Polycorp has supplied complete rubber linings in some of the largest ball mills in South America at 26

Learn MorePDF WHAT MAKES US - Growth SteelPDF

significantly from mill to mill. Growth Rubber has one of the best-equipped laboratory for testing and developing differentiated rubber compounds to suit your specific operation requirements. In conventional Mill Lining Systems, Growth Rubber offers a full range of rubber liners for • SAG Mills • AG Mills • Primary & Secondary Ball Mills

Learn MoreBall Mill Rubber Liner - IndiaMART

SAKAR's ball mill rubber liners are pressure moulded to ensure highest density and engineered for maximum abrasion resistance.

Learn MoreCompare the Benefits of Steel VS Rubber/Poly-Met Mill Liners

24/07/ · Let’s compare! Rubber Liners are better for abrasion grinding ie: cascade action but not for cataract mills. The graph below shows the increased operating cost of rubber and steel liners as the grinding ball size increases. Larger mill, larger ball increases the cost benefit of using steel only mill liners. Looking at this chart, any time

Learn More60 Duro Mill shell & liner backing rubber

Mill Backing Lining Rubber has been designed primarily for use as a wear and corrosion protection lining system. It is designed specifically to be used as

Learn MoreRubber Mill Liner (@rubbermillliner) • Instagram photos and

Rubber Mill Liner. Product/service. Dünyanın Lider Kauçuk Değirmen Astar ve Lifterbar Üreticisi The World's Leading Rubber Mill Liner Manufacturer

Learn MoreBall Mill Rubber Lining Rubber Liner

Rubber liner is mainly used in AG Mill, SAG Mill, Ball mill, Bar mill and other grinding equipments. Customers cover mining, cement, chemical industry, building

Learn MoreRubber Mill Liners Market Size 2022 Research Findings, Market Growth

In the forecast period of 2022-2026, the global "Rubber Mill Liners Market" is expected to grow at a steady rate, according to an Rubber Mill Liners Market report, which summarizes the key aspects of the market, as well as the leading key players, leading regions, and key applications. The report focuses on both qualitative and quantitative aspects of the market growth over 2022-2026.

Learn MoreRubber Mill Liners | Products & Suppliers | Engineering360

Description: The emphasis on liner design to ensure efficient mill operation has grown, particularly as mills have increased in size. The extent to which a liner effectively protects the mill, imparts energy and controls the mill charge, impacts on the total ownership . Form: Liner / Lining System Function & Thickness: Abrasion / Sliding Wear, Impact; Industry & Application:

Learn MoreRubber Mill Liners - Multotec

Rubber Mill Liners Multotec: protect mineral processing equipment from wear, abrasion and impacts. Supported globally. Monitoring software available.

Learn More