- [email protected]

- +86-21-63353309

tubing hanger installation procedure

tubing hanger installation procedure

Underwater completion expanding tu hanger - Google

The tu hanger running and retrieving tool assembly includes facilities to releasably connect the tool to the hanger, land and lock the hanger into the

Learn MoreTu Hanger Oilfield Equipment - Parveen Industries Pvt. Ltd

Tu Hanger Spool is used in combination with Tu Hanger coupling, Wrap around tu hanger (PTHSW) and 'PTHS' type tu spool. Tu Hanger Coupling

Learn MorePDF Casing & Tu HangerPDF

the top flanges of the spool. This type of hanger is used where tu must be rot ated or moved up and down under pressure. This tu hanger is used together with a tu hanger coupling and a tu hanger spool . NOTE: 1) X-API standard tu threads. 2) These hangers can also be offered with premium threads at request.

Learn MorePDF Method Statement for Installation of Fire Protection ServicesPDF

Anchor Installation) Refer figure 1. 3) Install Pipe Install the pipe either by screw fitting or welding. Refer to figure 2. 4) Install Hanger Rod Select the hanger based on the pipe size. Install the hanger rod to the drop in anchor. 5) Install Hanger Install the hanger to the pipe and the hanger rod. Refer to figure 3. 6) Tightening

Learn MorePipe Hangers & Supports - Safe Work Method Of Statement

Specification for Installation Method Statement of Pipe Hangers & Supports. PART-1 GENERAL: WORK INCLUDED: Compliance with relevant General Requirements of Mechanical Services. 1.2 DESCRIPTION OF WORK: This Section includes piping supports complete for all piping systems except as otherwise specifie. 1.3 Reference Standards.

Learn MoreCasing Head Housing, Casing Spool & Tu Hangers types

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn MoreTu hanger assembly and method of landing and locking

FIG. 1 is a fragmentary sectional view of a tu hanger assembly carrying a tu string and connected to a landing tool being run into a well casing means and prior to landing and locking.

Learn MoreSpecification for Installation Method Statement of Pipe Hangers

Provide one of the following types of hangers for horizontal piping manufactured by one of the approved makes. All Pipe Except Copper: Provide clevis type supports. Keep the clevis nut outside the insulation Where pipe exceeds maximum loading recommended for clevis type hangers, furnish steel pipe clamp.

Learn MoreWorkover programme - tu change out

8.6.3 Install a new 7" nominal DT seal in the tu hanger neck. Lightly coat the seal sub with anti-scuffing paste and also apply the lubricant to the GS seals and the tu hanger extended neck. 8.6.4 Pick up the tu bonnet by means of the two lifting eyes provided and carefully lower it over the tu hanger neck.

Learn MoreCasing Hanger - an overview | ScienceDirect Topics

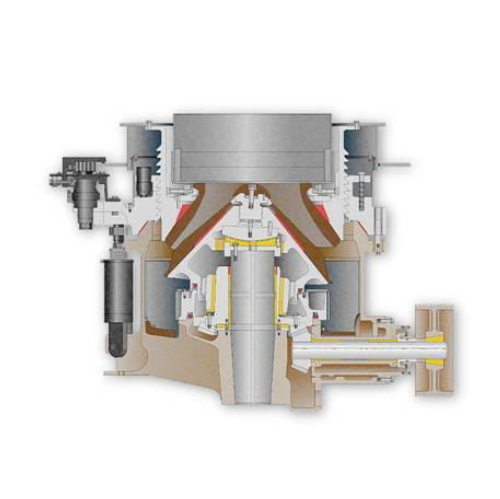

Tu hanger (TH) system is designed to suspend and seal the tu strings in the production bore of subsea well. TH shall be able to install through the BOP

Learn MoreDril-Quip DualBore Production System

Standard industry tools and procedures for orienting the tu hanger during installation; Includes orientation pin and orientation elevation check tool to

Learn MoreInstallation and Removal Tools For Type H Back Pressure Valves

A type H back pressure valve installation tool, also known as a stinger, is used to install type H back pressure valves and type H two way check valves in the tu hanger. This is a critical piece of equipment for putting back pressure and two-way check valves in place that will reduce downtime and minimize operating costs.

Learn MorePIPING and PIPE HANGER DESIGN and

of pipe hangers is an important part of the engineering study of any modern steam generating or process installation. Problems of pipe design for high temperature, high pressure installations

Learn MoreBack-Pressure Valve installed in tu hangers

Nov 28, · Left hand (anti-clockwise) rotation is applied to insert the valve. Once the valve is fully seated, moving the rod up to lift the pin from the slot and continuing a left-hand rotation

Learn MoreSpecification for Installation Method Statement of Pipe

5 rows · Where pipe exceeds maximum loading recommended for clevis type hangers, furnish steel pipe

Learn MoreUS6401827B1 - Tu hanger running tool - Google Patents

A running tool is used to install a tu hanger without entangling the continuous control lines. The tu hanger running tool is made up of a central

Learn MorePDF An Installer's Pocket Guide for Swagelok® Tube Fittings (MS-13-151;rev ...PDF

Fully insert the tube into the fitting and against the shoulder; rotate the nut finger-tight. High-pressure applications and high safety-factor systems: Further tighten the nut until the tube will not turn by hand or move axially in the fitting. Mark the nut at the 6 o'clock position. Swagelok Tube Fittings Up to 1 in ./25 mm

Learn MoreUpper Completion Advanced Designs: Spacing-Out Production Tu

May 03, · Safety-first, efficient practices are the primary concerns for most completion methods, and one critical area in completion practices is the spacing-out or landing of tu hangers. This process involves installation of the production string and associated components of a particular length within a certain measured-depth window.

Learn MoreCPVC Pipe Installation Instructions | FlowGuard Gold

Prepare the pipe and fittings (a) Remove any burrs or filings and bevel the end of the pipe using a chamfering tool. If a chamfering tool is not available, a sharp knife or file are suitable, but not preferred. Using a clean, dry rag wipe away any dirt and moisture from the joint surfaces.

Learn More